We’re committed to becoming the most sustainable business we can be, and we’re always striving to reduce our impact on the planet. It makes sense that we constantly review our product packaging and working to long-term sustainability goals.

RETHINKING PLASTIC

We’re a Catpack™, and that means the world to us. We’re one of 3,000 businesses worldwide to have the highest social and environmental standards for people and the planet, and we take that very seriously. Our focus is on CREATING SUSTAINABLE PACKAGING where possible; using more plant-based and recycled plastic and helping people around the world to reuse, repurpose and recycle.

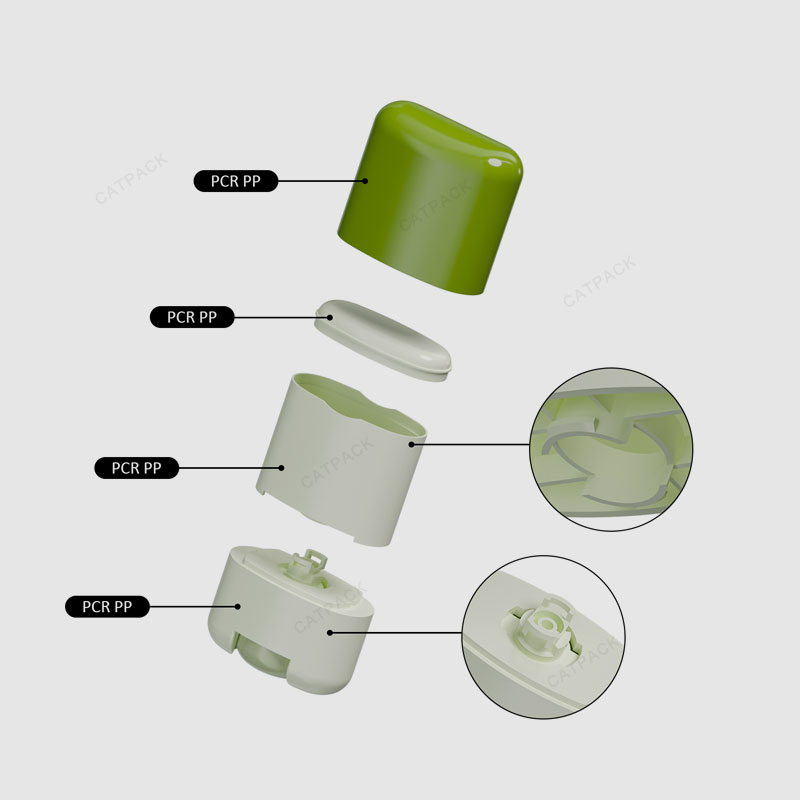

WE’RE USING MORE PCR IN OUR PACKAGING, AND ARE GRADUALLY ELIMINATING OIL-BASED PLASTIC.

GRS certifid post-consumer resin (PCR) is an environmentally-friendly packaging material in support of recycling programs.

Molded fiber can be broken down, decomposed, and returned to the environment through natural processes

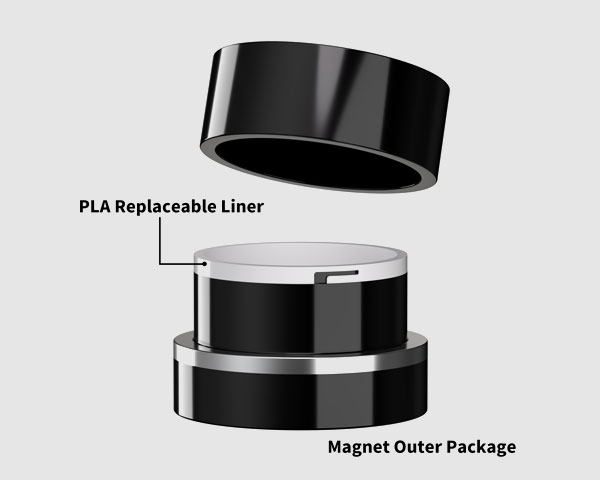

Refillable Design reduces waste and environmental impacts, save money for consumers, and be more convenient to use.

Multi-layer and composite plastic packaging is commonly used, but its recycling after use is cumbersome (requiring the peeling off of different materials of film and then disposing of them separately).

PCR, or post-consumer recycled plastic, is a material that is created from plastic waste that has already been used and discarded by consumers. It offers a number of environmental benefits, as it reduces the amount of new plastic that needs to be produced, conserves natural resources, and reduces greenhouse gas emissions. In addition, using PCR in the production of consumer products helps to reduce waste and promote circularity in the economy.

Many governments around the world have implemented policies to encourage the use of PCR, recognizing its potential to reduce the environmental impact of plastic production and consumption. By incorporating PCR into our products, we are able to contribute to the global effort to protect the environment and promote sustainable development.

Refillable Design reduces waste and environmental impacts,

save money for consumers, and be more convenient to use.

Join the refill revolution

From cream to skin care products to sunscreen deodorant sticks,

we're making it easier than ever to refill, reuse and repeat.

Welcome to send us information if any interests about COSMETIC PACKAGE designing and manufacturing.

Develop products that are compostable, refillable or returnable for repurposing.

Molded fiber can be broken down, decomposed, and returned to the environment through natural processes

PLA of Environmental Advantages

PLA is biodegradable under composting conditions and will decompose within 12 weeks

The manufacturing process of PLA is also more environmentally friendly than traditional plastics made from limited fossil resources. According to research, the carbon emissions associated with PLA production are 80% lower than traditional plastics

Influenced by the concept of Sustainable Development, Single Material Packaging is Valued

At present, it is common to use a variety of composite plastic packaging,

but its recycling and disposal after use is very troublesome and increases the cost.

(Different materials need to be peeled off and then disposed of separately).

Forced by ecological responsibility and local policy influence,

major global brands are beginning to commit to using a single material

NEWS

MORE CATPACK INFORMATION